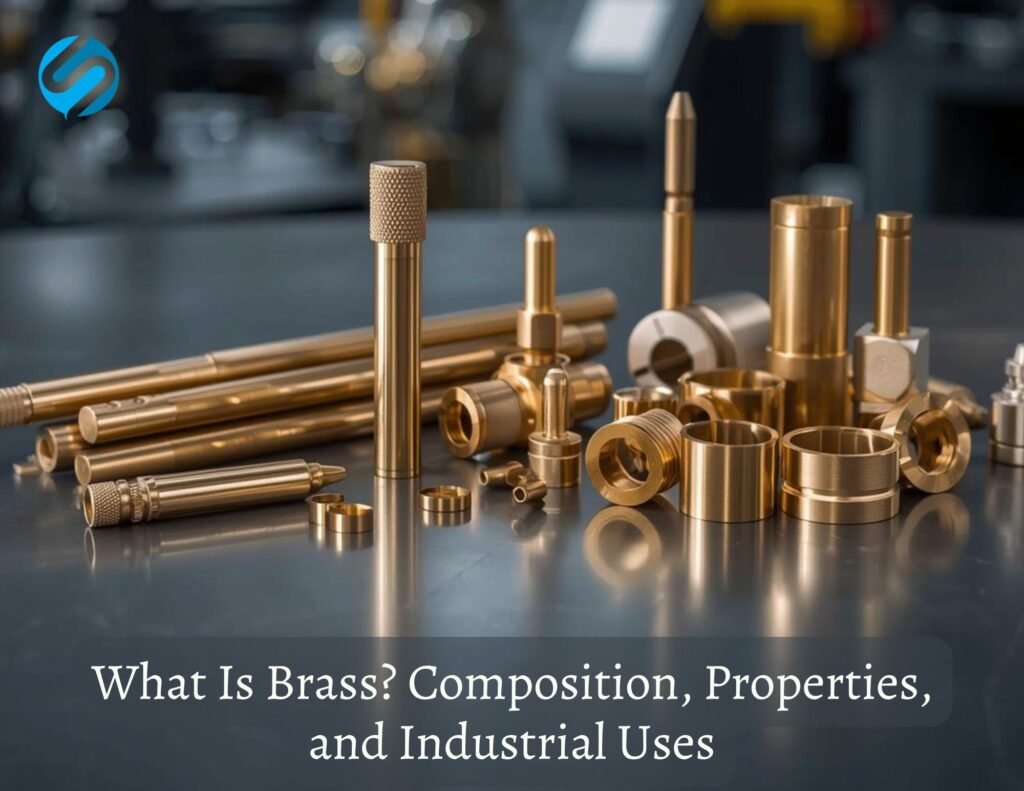

Brass has been an essential engineering material for its strength, durability, and workability for centuries. Knowing what brass is and what its features are helps manufacturers to select an appropriate material for applications that require precision, corrosion resistance, and long service life. Today’s brass plays an important role in electrical, plumbing, automotive, and industrial manufacturing all over the world.

This guide provides an answer to the question: what is brass, how is it made, what is it made of, what are its features, and how is it used in modern industry, with a primary focus on manufacturing in India?

What Is Brass and Why Is This Brass Important In Industry?

To answer the question what is brass, one needs to understand that brass is a metal alloy made by mixing copper and zinc. The mixture of metals determines the features to create brass for particular mechanical and physical requirements. When people ask what is in brass, the answer to what is brass, also involves the mixture of metals and adjusted industrial requirements.

Brass is a unique metal with so many qualities like good machinability, corrosion resistance, and conductivity, making it a good candidate for many industries and making it useful for a lot of things!

What is Brass Composition?

In order to understand the performance of this alloy, the next question is about what is brass composition. Brass composition is usually copper and zinc varying with different percentages; the brass composition is in a percentage. This lets manufacturers control the strength, toughness, and pliability of the alloy.

What is in Brass? In simpler terms, what is in brass?

At a fundamental level, what is in brass includes:

- Electrical conductivity and corrosion resistance is Copper, the main element of the brass.

- Zinc is also another main element that gives it strength and also improves the ease of making it.

and also some small amounts of other metals may also be included to improve some minor properties under some special brass grades. However, the core of what is brass composition remains the copper-zinc alloy system.

How Brass Is Made in Industrial Manufacturing

Knowing how brass is made gives a good idea why it is so good in other harsh working situations. The method is to melt the copper and zinc in controlled amounts into the brass alloy, and once both metals have been melted, the alloy is blended to ensure it is uniform throughout.

Brass Manufacturing Process Step by Step

- New tiles of copper and zinc are joined and melted.

- The alloy is then shaped to create bullets.

- The bullets are then machined, forged, or extruded.

Manufacturing techniques safeguard high quality and reliability and are patented to meet QoS and QoD. In large brasses, and tight tolerances, width, and length, the part produced is an industrial part.

Brass Properties and Uses in Industrial Applications

One of the main reasons brass remains widely adopted is due to its balanced performance. Brass properties and uses go hand in hand, as its characteristics directly influence where and how it is applied.

Key Brass Properties and Uses

- Resistance to corrosion, especially in moist environments

- Easy creation of machined parts for precision instruments

- Good electrical and thermal conductivity

- Strong yet flexible structure

These qualities and attributes are in high demand. Brass performs exceptionally well across many industries. These industries are for attribute accent accuracy. Brass is used in lasting fittings and in connectors and in mechanical parts. Accurate parts are lasting.

What Is Brass Used For Across Industries?

What is brass used for? It’s a common inquiry among manufacturers that request a quote for brass component manufacturing. Common applications of brass include electrical equipment, plumbing, automotives, and industrial machinery.

In precision manufacturing, what is brass used for tends to be specific to parts that require tight tolerances and dependable functionality. Brass is a staple for these industries for the timely and operationally compliant brass components.

From connectors to fasteners, what is brass used for is becoming increasingly common and diversified as industries require new materials that meet a balancing point of optimal cost and functionality.

Where Is Brass Found In India?

India exports a tremendous amount of brass and has a considerable role in global brass supply chains. Knowing where is brass found in India helps explain the country’s importance in global supply chains. Some regions have developed specific and unique competencies in brass processing and in elaborated brass components manufacturing.

Major Brass Manufacturing Regions

- Jamnagar, Gujarat

- Other industrial clusters across western India

These regions are known for their efficient production and fine craftsmanship. Regarding where is brass found in India, Jamnagar is considered a global center for brass components and fittings. Large-scale production is made possible by the intersection of developed infrastructure, abundant skilled labor, and efficient production.

Uses of Brass Metal in Modern Industry

The uses of brass metal extend across multiple sectors due to the alloy’s adaptability. Brass is widely used in:

- Electrical and electronic devices

- Plumbing and sanitary fittings

- Automotive and mechanical assemblies

- Industrial hardware and precision components

Brass’s adaptability guarantees its significance in manufacturing, including older technologies and practices.

Brass Components for Industrial and Commercial Purposes

Brass’s reliability for large-scale manufacturing and adaptability for engineering applications are primarily responsible for its increasing popularity in manufacturing brass components for industrial applications. Manufacturing brass components relies on brass for safety, performance, and durability. For a broader perspective, you can explore Brass Components for Industrial and Commercial Use, which highlights how brass supports diverse industrial applications.

Why is Brass Suitable For Many Applications in Precision Manufacturing?

Why is brass the first material considered among the many metals available to the industry? The most obvious reason is that it is the easiest to work with. It is a metal that provides, among other things:

- Free machining, no loss of eroding material from the tools

- Dimensionally stable, the metal components do not change in size

- Long-lasting performance under extreme conditions

These characteristics are the reason brass has such a strong record in engineering applications that require consistent and high accuracy.

Why Brass is the Most Preferred Industrial Material

Brass is the most preferred industrial material as it provides the manufacturers a strong, a high degree of workability, and strength to create intricate designs. This is the reason why brass is a dominant construction material.

Conclusion

Knowing what is brass would mean more than knowing the components of the brass, but showing the impact it has on the modern world of manufacturing. One’s knowledge of how brass is made and what is brass used for gives an insight into the versatility of this alloy and explains why it is an essential brass alloy. One can find brass in conditions used for industrial development in various parts of India, and its versatility explains why it continues to support industrial growth.

Brass is a combination of a wide range of uses and efficient manufacturing processes. This shows its importance in both today’s and the past needs of the industry.